STP FLOW is an innovative car body protection coating, based on the STP pre-polymer. STP FLOW forms a durable and permanently elastic coating with excellent anti-gravel and sound-deadening properties. STP FLOW can be applied by air spraying, to render a finish that helps restore the texture of the OEM anti-gravel chassis coating. STP FLOW is based on a state-of-the-art hybrid resin production process, which matches the high strength of polyurethane with the flexibility, high adhesion and weather resistance typical of siloxane formulations. STP FLOW is isocyanate-free for exceptional processing without exposure to toxic ingredients. STP FLOW is easy to apply, featuring good stability and high substrate adhesion.

STP FLOW features:

The product consistency helps build textures with a higher spread. For application by air spraying.

TECHNICAL DATA SHEET SAFETY DATA SHEET

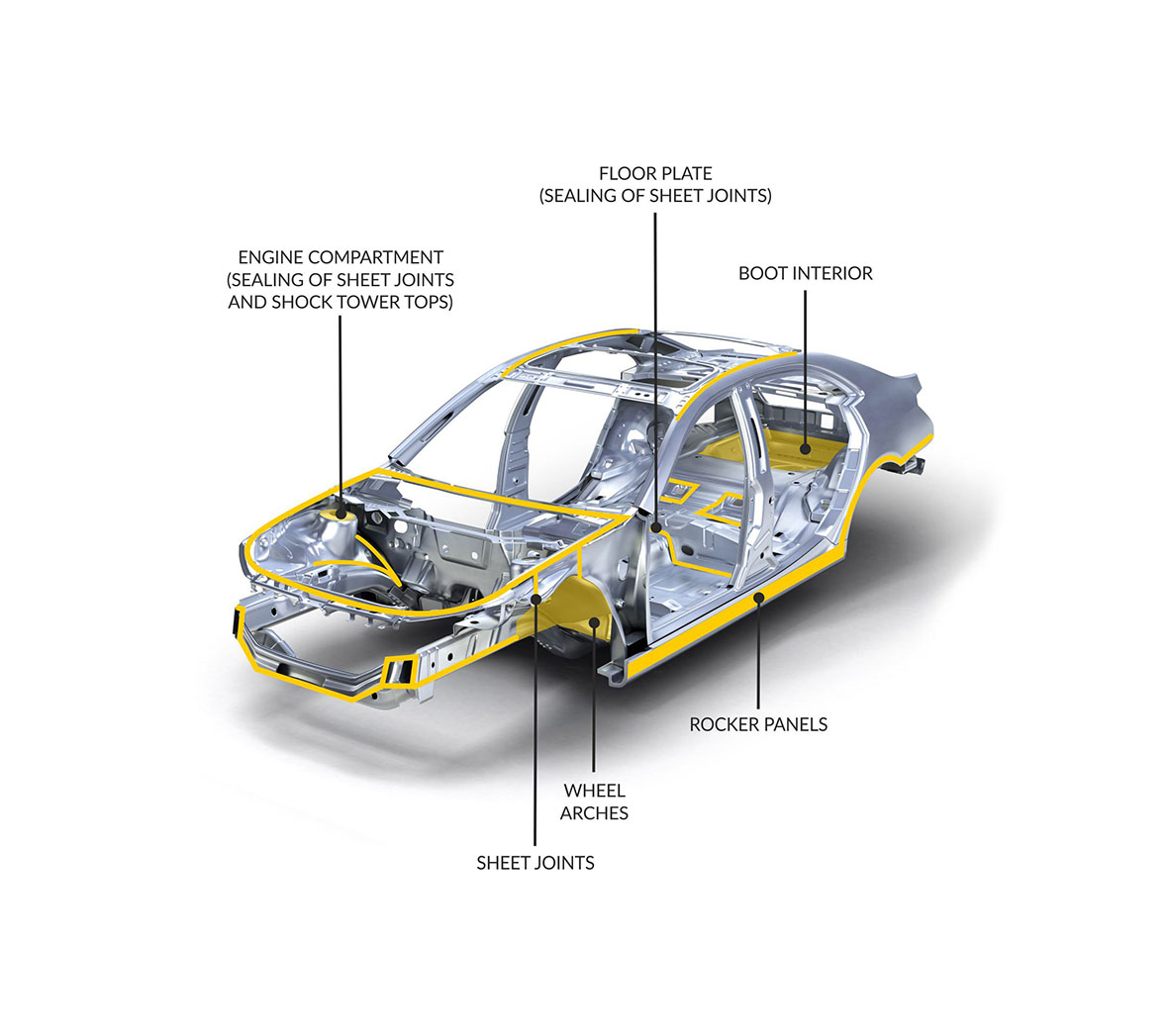

STP FLEX is an STP resin-based sprayable hybrid sealant. The product is intended for sealing and protection of overlapping and welded metal sheet joints of motor vehicle bodies and regeneration of OEM-deposited sealant textures. The final texture varies with the specific gun nozzles from thin stripes to dashed.

STP FLEX features:

The STP FLEX Sprayable Sealant ensures perfect adhesion to bare (non-primed) substrates (carbon steel, galvanized sheets and aluminium), acrylic or epoxy basecoats, and old paint coats. The product can regenerate the original sealant textures on car bodies.

TECHNICAL DATA SHEET SAFETY DATA SHEET

Nozzles available

Recommended application temperature: 15°C to 25°C.

Operate the piston to feed out 1 to 2cm of the product before installing the cartridge in the spray gun.

The sealant is applied with special spray guns that must be operated according to their manufacturers’ guidelines.

Only STP FLEX: applied with manual or pneumatic extrusion guns. Certain finish textures require the sealant to be heated.

STP GLASS is a high decking, fast curing, one-component, flexible and high performance polyurethane adhesive for direct glazing of the vehicle glass. It is designed for bonding windscreens, side and rear windows to passenger cars, trucks, tractors and special vehicles. Also used for bonding fibreglass reinforced plastic elements (roofs, side and frontal panels) on vehicles. It can be used in all applications where a strong elastic structural bonding to elements of different compositions (automotive top coat paint, metal sheets, fibreglass and reinforced plastic) is necessary and that undergo a strong mechanical or thermal stress. It is specifically designed to give a fast and safe drive-away time on vehicles fitted with airbags in 1 hour. Suitable for use with integrated antennas or other electrical devices.

TECHNICAL DATA SHEET TECHNICAL DATA SHEET (PRIMER)SAFETY DATA SHEET SAFETY DATA SHEET (PRIMER) Leaflet STP GLASS